INDOOR AIR QUALITY

The quality of air in the built environment has a significant impact on human health and comfort. Poor IAQ can lead to discomfort, ill health, building related illness and reduce productivity.Poor IAQ is an important occupational and environment issue. Proper filtration can also stop the spread of illness including the flu or the commond cold. It can protect livestock from similar illness and reduce machinery downtime.The most important part of indoor Air quality is the cleanliness of the air. Air contamination consist of particles, gases and vapours that may reduce the well-being and health of humans and decrease the output and efficiency of production processes.

Recent

studies suggest indoor air quality (IAQ) and productivity of employees are

related factors. Healthy air quality directly contributes to the performance of

staff.

HOW AIR FILTRATION IS VITALLY IMPORTANT

Although the operation of a filter may appear very simple in theory, filters are in fact highly complex products. The filter fibers have to allow sufficient air to pass through – without offering too much resistance – while also trapping harmful particles. This is the strength of good filters.

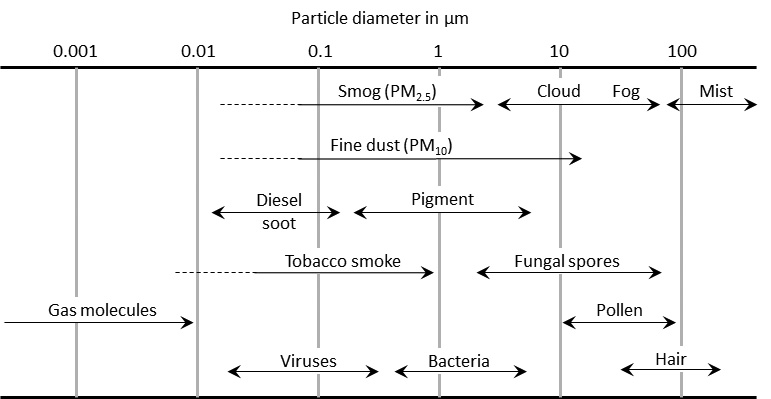

During the past few years, increasing attention has been drawn to the hazards of fine particles; air pollution in the form of particles which are smaller than 10 microns. Busy roads, industry, combustion engines and the bioindustry are major sources of fine particles. Smaller particles can penetrate deep into our lungs, where they may cause substantial damage to health. Children, the aged and people with respiratory complaints are particularly susceptible. Apart from protecting people, filters can also be used to guarantee the progress of operating processes. The applicable filter requirements naturally vary, depending on the type of operating process in question.Poor air quality during the execution of production processes in the pharmaceuticals sector can have far-reaching consequences.The use of superior quality filters is therefore crucial if the production of medicines in a manufacturing plant is to proceed without complications.

For hygiene reasons, bacterial and fungal spores must be removed from the air stream, which are typically in a size range between 1 and 10 μm (See Figure ). Therefore, for the human health and indoor hygiene, it is important to clean the inlet air with sufficient air filters.

Figure; General guide to particle size distribution of common atmospheric contaminants